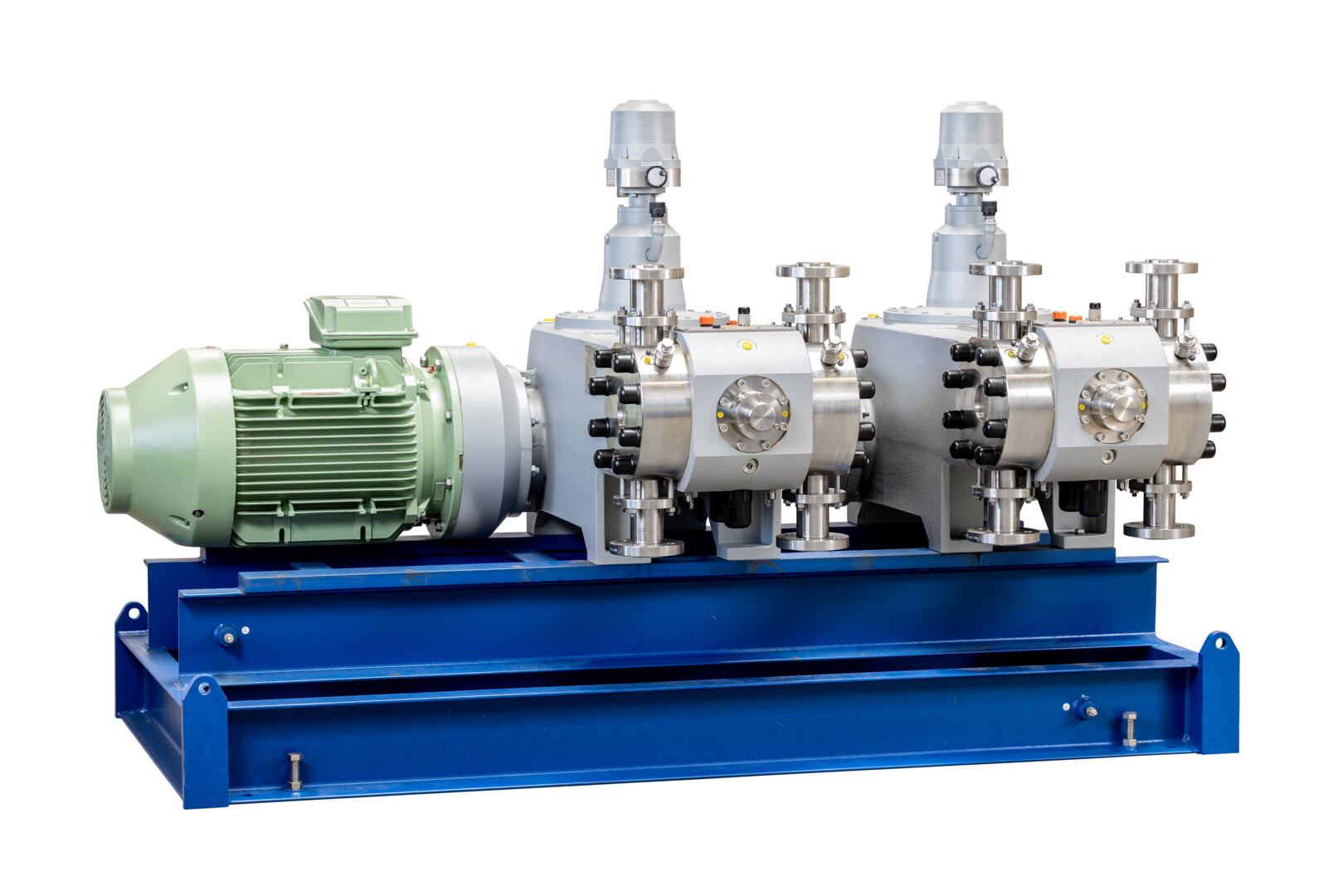

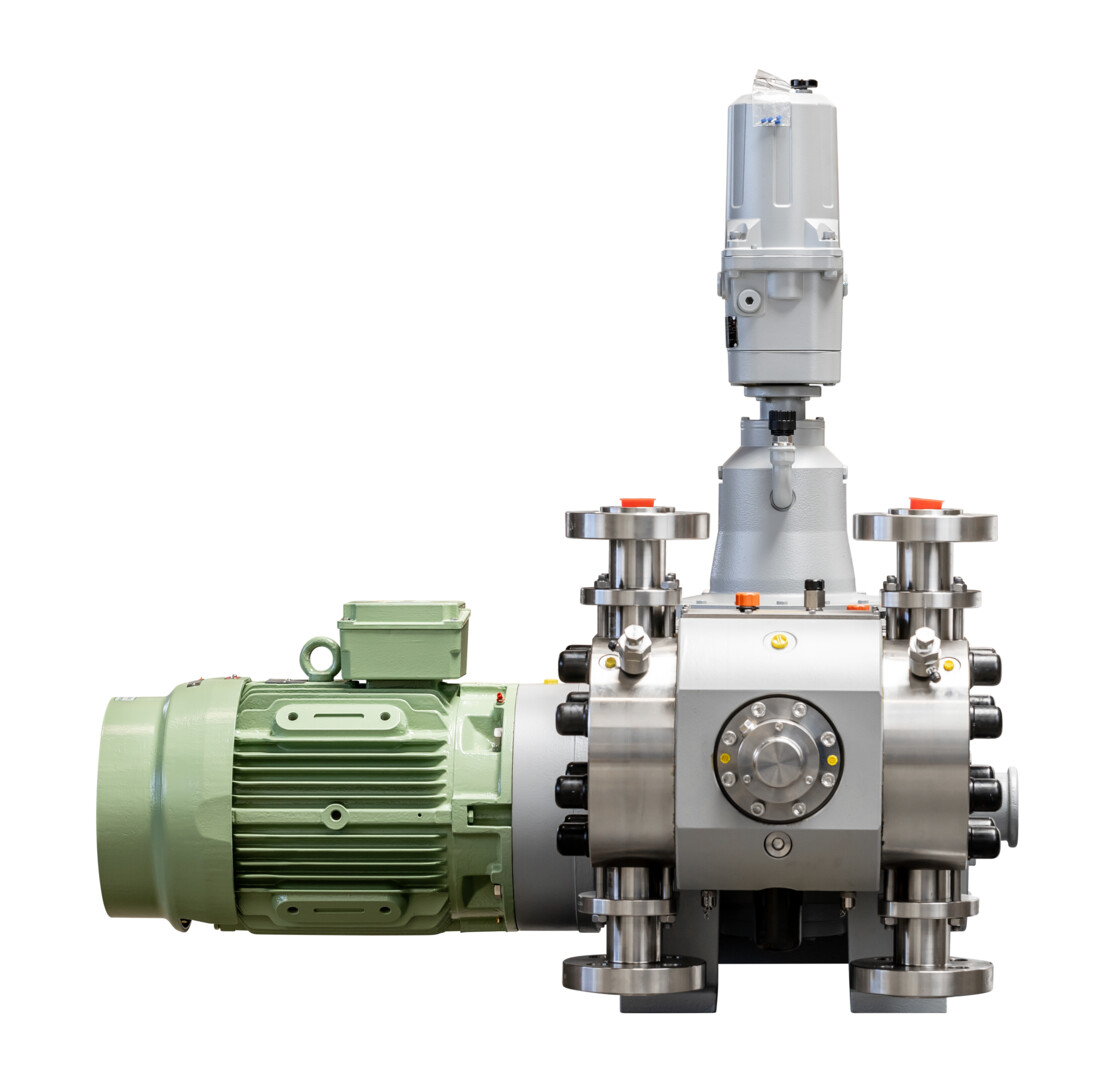

NOVADOS Double-Acting Double Diaphragm Pump

Product Type(s) : Diaphragm Pumps

Description :A Compact Solution

Description

FEATURES

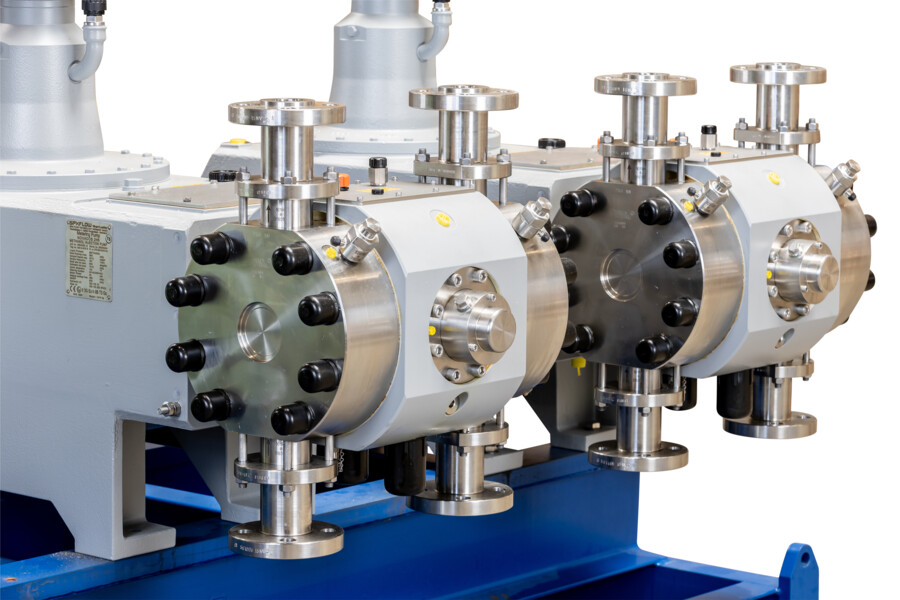

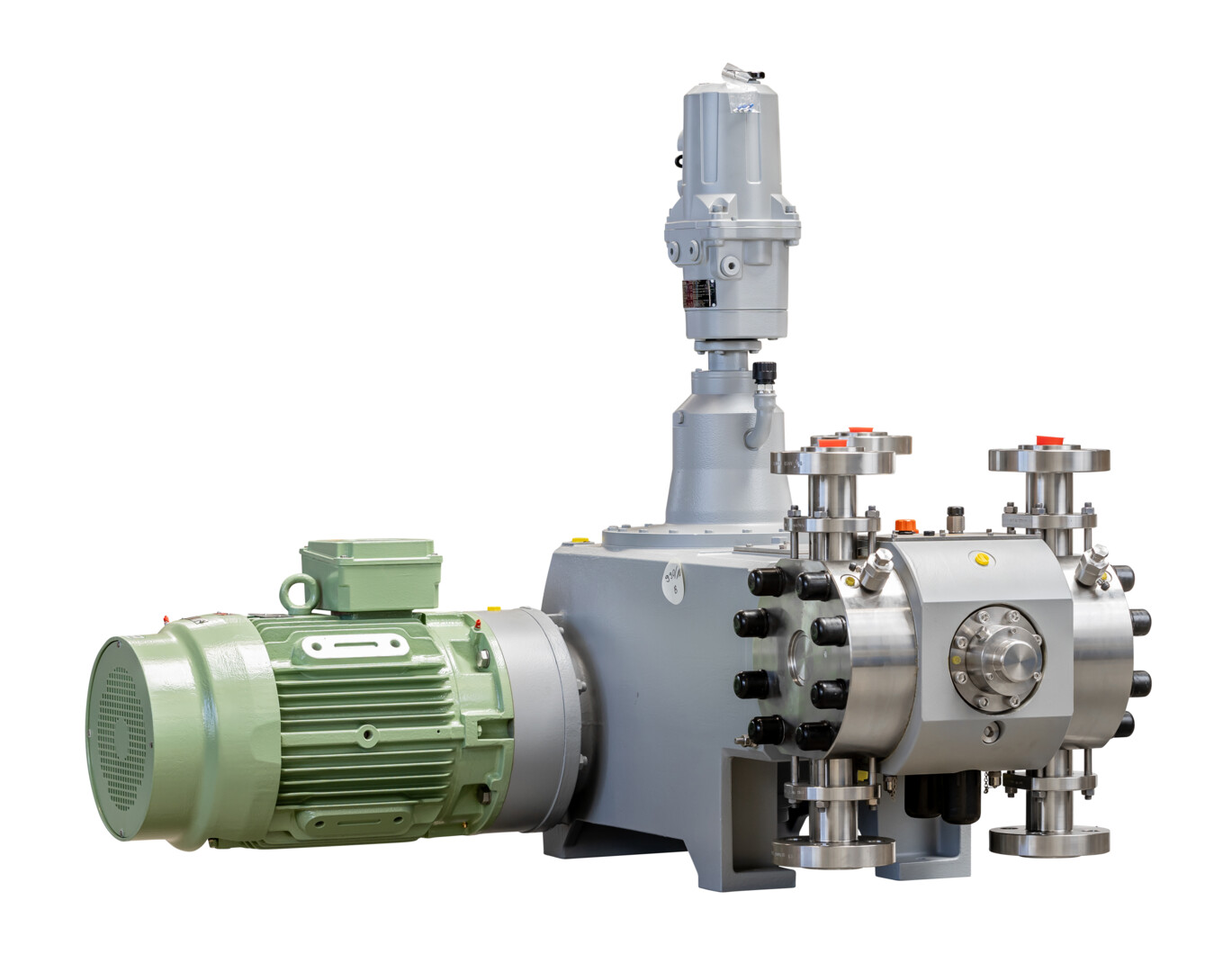

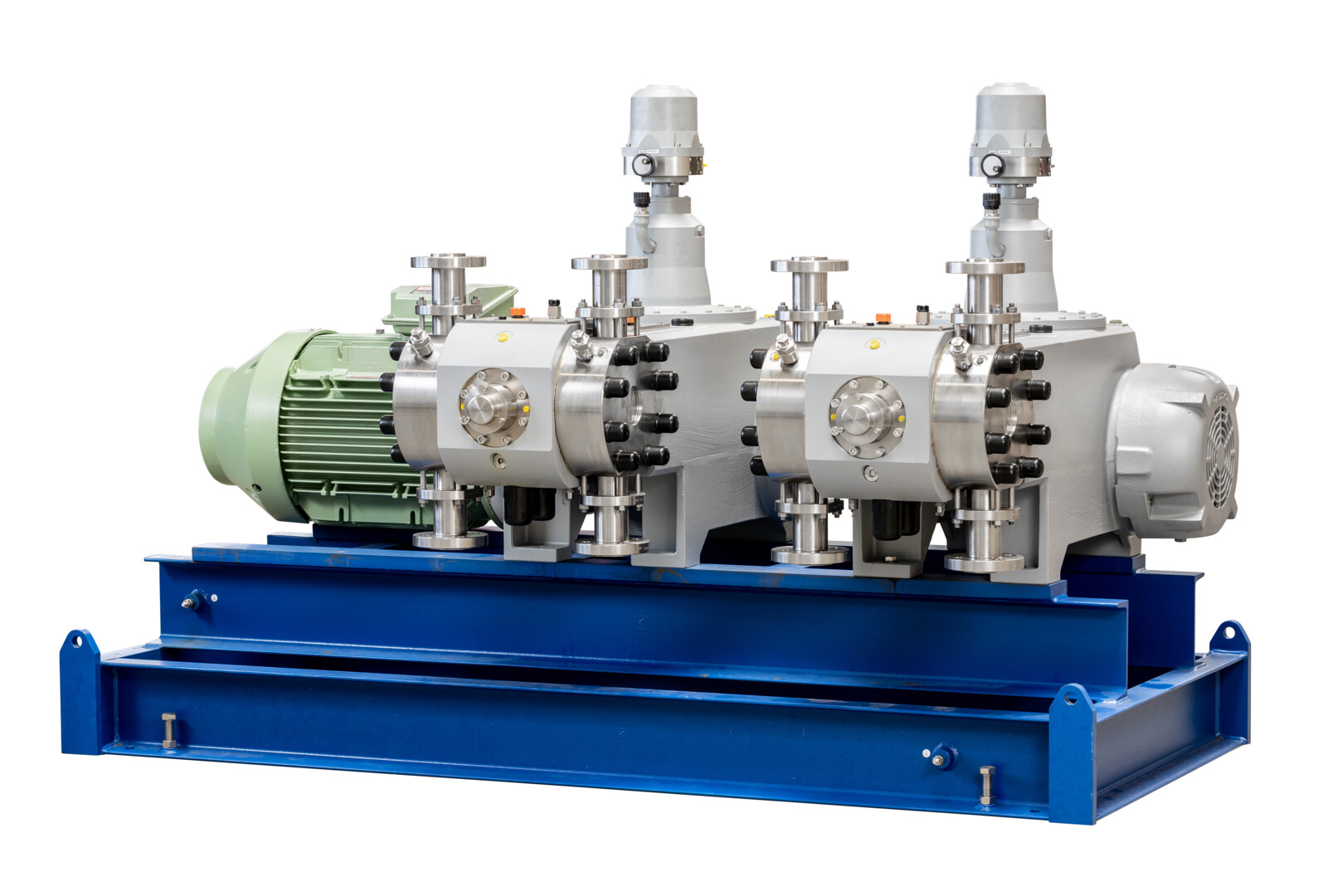

The NOVADOS Family comprises leak-free diaphragm pumps as well as plunger pumps. Nearly all gear sizes in the NOVADOS series can be combined to achieve the required flow rate and pressure parameters. A Compact Solution In diverse industries including oil and gas, chemicals, and synthetic processes, the utilization of multiple pumps is common practice to ensure optimal flow rates. Traditionally, the duplex pump head pump has been favored by companies. However, this choice may inadvertently compromise efficiency, space utilization, and weight management. Embracing the innovation of double-acting double diaphragm pumps (DADD) presents a solution that not only addresses these issues but also unlocks various advantages. Particularly noteworthy are the reduced footprint, lighter load, and enhanced flow rates achievable through the implementation of DADD pumps.

DIMENSIONS & SPECIFICATIONS

Materials of construction of liquid-wetted parts

- Housings of stainless steel 1.4571 or 1.4462, or plastic PVC or PP

- Diaphragms of PTFE or stainless steel 1.4310

- Plungers of stainless steel or ceramic

- Options: materials such as Super Duplex, Hastelloy, Titanium and other materials

Pump gear design

- Worm gear with different reduction ratios

- Splash lubrication

- Stroke length adjustment via eccentric (Z-shape) crankshft

Flow rate control

- Manual, electric, or speed variation

Drive

- Electric motor with fixed or variable speed

- Other drives on request

Installation and Operating Conditions*

- Hazardous area:up to Zone 1 IIC T4 (Zone 22 upon request)

- Ambient temperature range: from -40 °C up to +50 °C (special solutions upon request)

- Fluid temperature range: from -40 °C up to +150 °C (special solutions upon request)

*These are limit values, please state actual conditions with inquiry.

Benefits

- Hermetically sealed pump design

- Optimal capacity adaptation to widely varying production processes

- Variable stroke length for each pump allows independent flow rate adjustment of each pump component

- Variable speed drive allows flow rate variations while maintaining

- Automation allows higher production efficiency to be achieved

- Existing installations can be altered or expanded with extra pumps or automatic control

- Multiple pumps with up to 12 pump heads are available

OPTIONS & PERFORMANCE

Advanced Flow Control Solutions

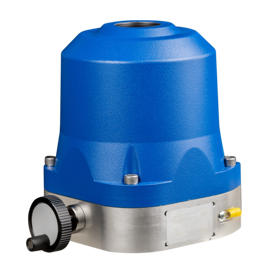

The ARIS ExTensor and Tensor TS Flow Control Actuators are engineered for exceptional durability, aligning with the lifespan of Bran+Luebbe NOVADOS Series pumps. These adaptable flow control solutions enable precision adjustments in under a second, streamline onsite commissioning, and integrate seamlessly with existing process control systems for remote operation. The ARIS ExTensor’s robust design ensures reliable performance in harsh and explosive environments, enhancing plant efficiency and conserving resources.

These actuators are multi-turn rotary devices connected to the pump’s stroke length adjustment unit, modulating the stroke length and thus the flow rate of the pump. Controlled by a standard electrical signal (e.g., 4-20mA), the actuator adjusts the stroke to the desired position between 0% and 100% of the maximum stroke length.

Features:

- Universal Actuator: One actuator type for H1-H6 NOVADOS Series pumps.

- Reduced Commissioning Time: Simple and fast installation and programming

- Remote Control Connectivity: Integrates with your existing process control systems for remote stroke adjustment capability.

- Built for Continuous 24/7 Operations: S1 Operating Mode

- ATEX Certification: The ARIS ExTensor is certified for Ex-Zone IIC*

*ARIS ExTensor only, not applicable for Tensor TS

Reviews

There are no reviews yet.