Description

Always providing the right spin at precisely the right time

SIMOTICS torque motors – highest precision for rotary axes

SIMOTICS T-1FW3 complete torque motors – for applications with high torques

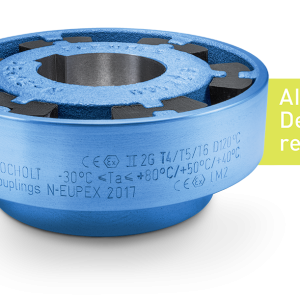

Complete torque motors are permanent magnet AC synchronous motors that are used as a replacement for hydraulic and conventional electric drives, consisting of electric motor and gearbox or belts. They are especially suited for use as direct drives in applications with a torque range of 100 Nm to 7.000 Nm at speeds of 50 to 1.800 rpm.

Complete torque motors are delivered factory-assembled.

The extremely compact, water-cooled SIMOTICS T-1FW3 complete torque motors are flanged to the machine using torque arms specifically developed for the purpose. An optional clamping element makes it easier to couple the rotor to the machine shaft. The pre-installed mounting set includes the torque arm, clamping element and centering sleeve (only for hollow shafts) – making it simple and safe to establish a connection to the motor. This creates a perfectly stiff drive train that can be optimally controlled.

SIMOTICS T-1FW6 built-in torque motors – for applications with very high torques and high precision

Built-in torque motors are liquid-cooled resp. self-cooled high-pole permanent excited three-phase synchronous motors with hollow-shaft rotor. The motors are supplied as built-in components. For a complete drive unit, a bearing and an encoder system are required additionally.

For SIMOTICS T-1FW6 built-in torque motors, stator and rotor are supplied as components and are directly integrated in the machine itself. They are available with jacket as well as with integrated cooling. Further, the motors operate without any mechanical transmission elements – e.g. coupling and gearbox – and require significantly less space than conventional drives. The compact design and low number of installed parts reduce the number of interfaces, maintenance costs and stock inventory costs – thus minimizing machine failures.

Technical overview

*depending on the version and type

SIMOTICS T benefits & applications

- Highest precision, power and dynamic performance

- Various application-specific versions

- Direct controllability; no elasticities in the drive train

- Low space requirement and simplified maintenance as the motor can be directly integrated into the machine structure without having to use mechanical transmission elements

- High number of poles for high torques at low speeds

- Short acceleration times and very high smooth running characteristics

- High degree of efficiency

- High degree of availability

SIMOTICS T-1FW3

Process industry

Plastic industry

Marine solutions

Metal forming

SIMOTICS T-1FW6

Rotary indexing machines

Rotary indexing tables and partial machines

Rotary axes (A/B/C for 5-axis machining centers)

Workpiece spindles

Roll and cylinder drives

Test stands

Reviews

There are no reviews yet.