Description

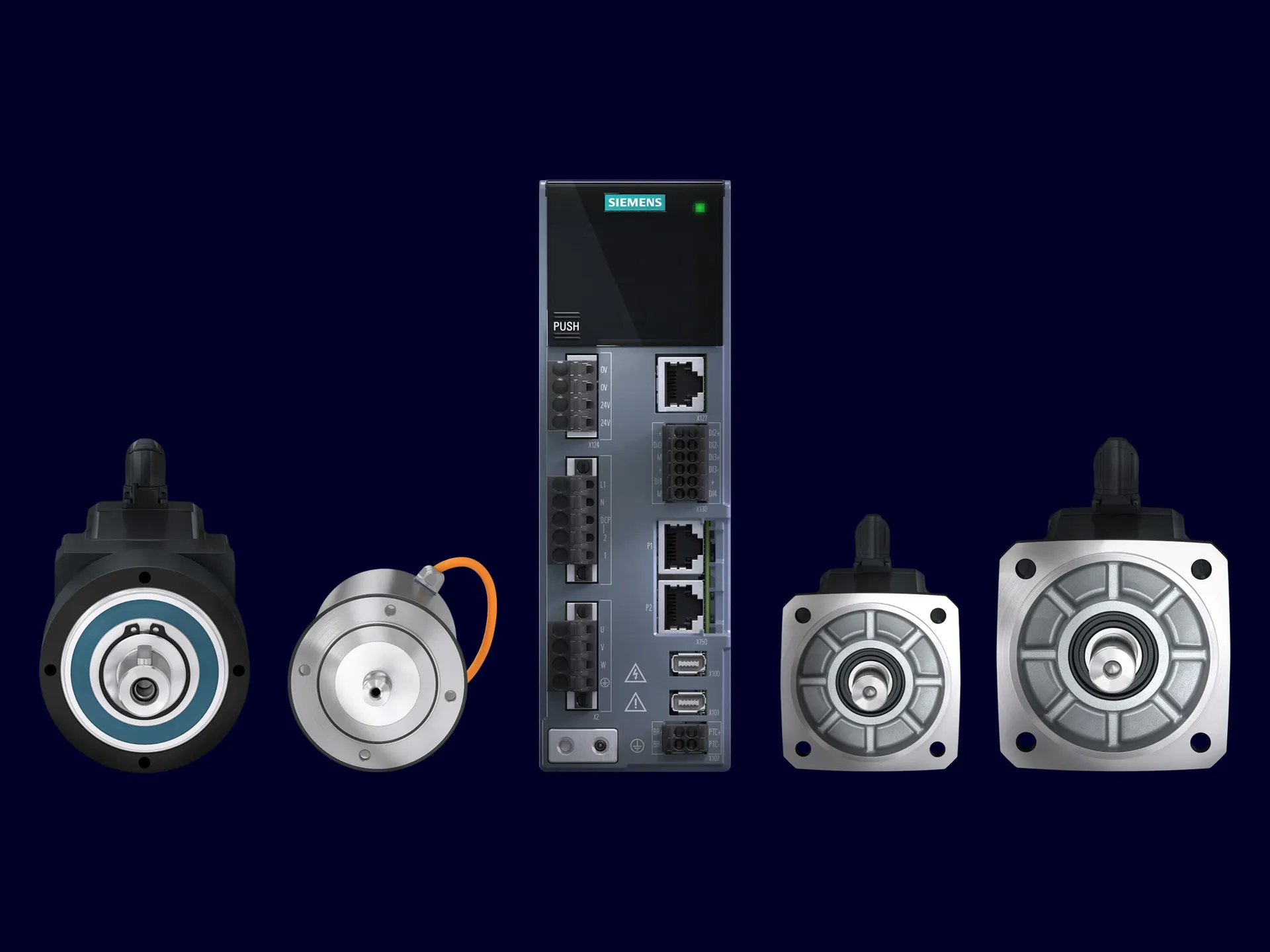

SINAMICS S210 – The servo drive system for high-dynamic applications

The SINAMICS S210 servo drive system is setting higher standards for dynamic applications in many industries thanks to improved hardware and software as well as integrated safety and technology functions. The SINAMICS S210 system consists of a servo drive and a servo motor and is designed for solutions with high dynamics in the power range from 50 W to 7 kW. Discover your possibilities.

Efficient Motion Control -Teamwork enhances drive applications effectiveness

Siemens offers a holistic system approach for motion control applications in the field of basic automation with its single-axis servo drive system, SINAMICS S210, and the new controller, SIMATIC S7-1200 G2.

Selecting step by step

From the ideal servomotor for your application, the optimum servo converter along with suitable cables and connectors up to the right controller for you – we will explain step by step how you get to your servo drive system.

Step 1: Simulation of your motion control application

Add the Digital Twin of the drivetrain to your machine simulation – speed up your design and engineering phase, while improving machine quality and robustness! DriveSim Designer and DriveSim Engineer are the ultimate solutions for designing, commissioning and optimizing your drive train system.

Step 2: The ideal servomotor

Step 3: The optimum servo drive

SINAMICS S210 servo converter

The SINAMICS S210 servo drive covers a power range from 0.1 up to 7 kW. In conjunction with a SIMOTICS servomotor from the S-1FK2 or S-1FT2 product series, the system is predominantly designed for discontinuous applications in the machinery construction domain that require a high dynamic performance. SINAMICS S210 fully leverages its strengths when the application involves precise positioning and motion control. Even with the highest dynamic performance, all motion sequences are implemented with the utmost precision. With its outstanding performance, SINAMICS S210 is convincing in packaging machines as well as in handling systems, in woodworking and plastics processing as well as in digital printing.

Step 4: The matching cables

Motor connecting cables – OCC (One Cable Connection)

All motors and frequency converters of the SINAMICS S210 servo system are connected up using just one single cable – this transfers the power, connects an encoder and controls the brake. Simple connection without special tools.

Available cables:

- MOTION-CONNECT 400 for fixed routing (only for SIMOTICS S-1FS2)

- MOTION-CONNECT 500 cables are used for predominantly fixed routing

- MOTION-CONNECT 800PLUS cables when routing cables in moving cable carriers (drag chains).

The cables can be ordered prefabricated with the required length.

Motor connecting and extension cables

- Prefabricated OCC motor connecting cable with SPEED-CONNECT plug connector on the motor side (shield terminal included in the scope of delivery)

- Prefabricated OCC motor connecting cable with SPEED-CONNECT plug connector on the motor side and Siemens IX signal connector on the converter side (shield terminal included in the scope of delivery)

- Prefabricated extension cable

Step 5: The matching controller

Step 6: The user-friendly accessory for your operation

SINAMICS Smart Adapter

The Smart Adapter complements the system as a helpful plug-and-play device. During commissioning, operation, or diagnostics, it enables a wireless connection (via WiFi) between a mobile device or laptop and the SINAMICS S210 servo drive system. Due to its small size, it is ideal for carry-on luggage and can be used without additional charging or batteries.

Planning, configuring, engineering and commissioning

Selection tools

- The SINAMICS Selector App helps you conveniently find the right drive on your smartphone.

- The Siemens Product Configurator (SPC) assists you in configuring your drive.

- The TIA Selection Tool (TST) supports you in defining the mechanics as well as selecting and designing drives and motors. SIZER for Siemens Drives provides project results and calculations for performance and energy consumption.

- Simulation and virtualization with the Digital Twin.

Commissioning tools

- The integrated web server ensures efficient setup, diagnostics, and maintenance – combined with features like the SINAMICS Smart Adapter for Wi-Fi connection and more.

- SINAMICS Startdrive in TIA Portal supports the step-by-step commissioning and integration of the system into the automation environment.

Reviews

There are no reviews yet.